Kæbeknuser ny Fabo 200-350 TPH Crushing Screening and Washing Plant

- 2024

- 24 Timer

- 38160 Chatte

|

Væsentligste oplysninger

|

|

|---|---|

| Sitereference : | 10267301 |

| Type | Knuser |

| Undervogn | Kæbeknuser |

| Mærke | Fabo |

| Model | 200-350 TPH Crushing Screening and Washing Plant |

| Tilstand | Ny |

| År | 2024 |

| Land | FRANKRIG |

| Fabrikant | Fabo |

Hovedspecifikationer |

|

|---|---|

| Kapacitet | 350 tonnes |

Egenskaber Fabo 200-350 TPH Crushing Sc... |

|

|---|---|

| Antal timer | 24 timer |

Bemærkninger |

|---|

|

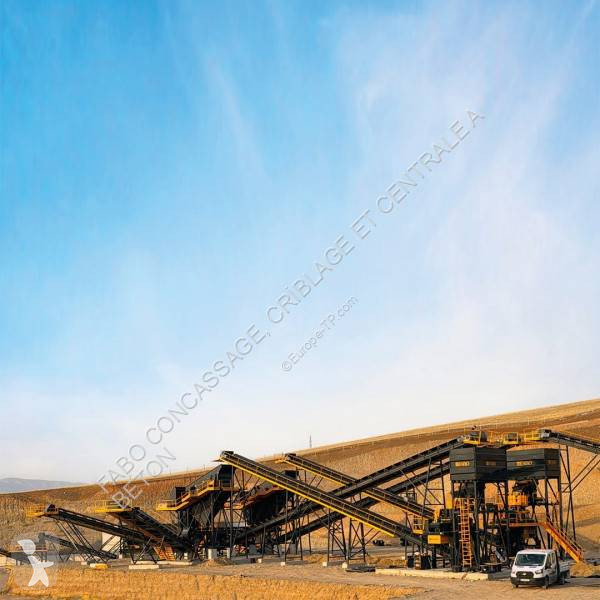

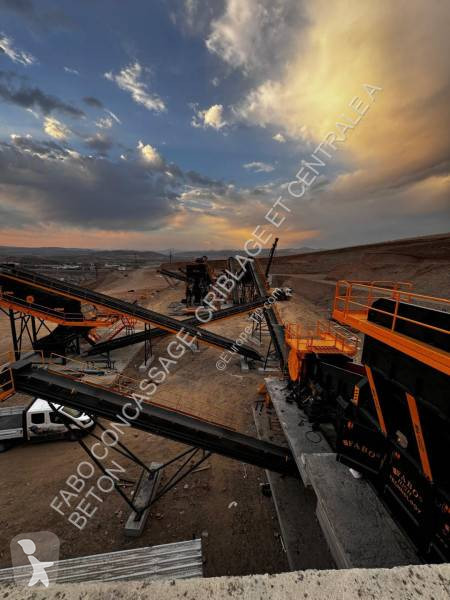

Our stationary crushing and screening plant, with a capacity of 200-350 tons per hour, consists of a 30 m³ vibrating feeding bunker, mid-screen, CLK-110 jaw crusher, cone crusher, vertical shaft impact crusher, stock and return conveyors, control cabin, and automation system. Products transferred to the feeding bunker are separated from dirt and mud using the intermediate screen and are bypassed with a bypass conveyor. The material above the screen goes to the jaw crusher, while the products on the second level drop onto the jaw discharge conveyor, and the products on the lowest level are discarded as bypass. The jaw crusher has a maximum feeding capacity of 800 mm and crushes the products, which first go to the washing screen. Here, the finest products are sent to the stock area with a screw washer, and the other products are sent to the cone crusher. The products coming out of the cone crusher are directed to the other screen and the vertical shaft impact crusher, allowing the desired products to be obtained from the final screen at high quality.

TBX-30 Vibrating Feeding Bunker CLK-110 Jaw Crusher TE-2060x3 2000x6000 3-Deck Vibrating Washing Screen HY-800 8000x8000 Screw Washer 20m3 Cone Crusher Feeding Bunker CC-300 Cone Crusher 20m3 Vertical Shaft Impact Crusher Feeding Bunker VSI-900 Vertical Shaft Impact Crusher TE-2060x4 2000x6000 4-Deck Vibrating Screen TE-2060x3 2000x6000 3-Deck Vibrating Screen Conveyor Belts, Control Cabin, Electrical Panel, and Automation System |

|

Voir tout

|

Bemærkninger |

|---|

|

Our stationary crushing and screening plant, with a capacity of 200-350 tons per hour, consists of a 30 m³ vibrating feeding bunker, mid-screen, CLK-110 jaw crusher, cone crusher, vertical shaft impact crusher, stock and return conveyors, control cabin, and automation system. Products transferred to the feeding bunker are separated from dirt and mud using the intermediate screen and are bypassed with a bypass conveyor. The material above the screen goes to the jaw crusher, while the products on the second level drop onto the jaw discharge conveyor, and the products on the lowest level are discarded as bypass. The jaw crusher has a maximum feeding capacity of 800 mm and crushes the products, which first go to the washing screen. Here, the finest products are sent to the stock area with a screw washer, and the other products are sent to the cone crusher. The products coming out of the cone crusher are directed to the other screen and the vertical shaft impact crusher, allowing the desired products to be obtained from the final screen at high quality.

TBX-30 Vibrating Feeding Bunker CLK-110 Jaw Crusher TE-2060x3 2000x6000 3-Deck Vibrating Washing Screen HY-800 8000x8000 Screw Washer 20m3 Cone Crusher Feeding Bunker CC-300 Cone Crusher 20m3 Vertical Shaft Impact Crusher Feeding Bunker VSI-900 Vertical Shaft Impact Crusher TE-2060x4 2000x6000 4-Deck Vibrating Screen TE-2060x3 2000x6000 3-Deck Vibrating Screen Conveyor Belts, Control Cabin, Electrical Panel, and Automation System |

|

Væsentligste oplysninger

|

|

|---|---|

| Sitereference : | 10267301 |

| Type | Knuser |

| Undervogn | Kæbeknuser |

| Mærke | Fabo |

| Model | 200-350 TPH Crushing Screening and Washing Plant |

| Tilstand | Ny |

| År | 2024 |

| Land | FRANKRIG |

| Fabrikant | Fabo |

Hovedspecifikationer |

|

|---|---|

| Kapacitet | 350 tonnes |

Egenskaber Fabo 200-350 TPH Crushing Sc... |

|

|---|---|

| Antal timer | 24 timer |

Bemærkninger |

|---|

|

Our stationary crushing and screening plant, with a capacity of 200-350 tons per hour, consists of a 30 m³ vibrating feeding bunker, mid-screen, CLK-110 jaw crusher, cone crusher, vertical shaft impact crusher, stock and return conveyors, control cabin, and automation system. Products transferred to the feeding bunker are separated from dirt and mud using the intermediate screen and are bypassed with a bypass conveyor. The material above the screen goes to the jaw crusher, while the products on the second level drop onto the jaw discharge conveyor, and the products on the lowest level are discarded as bypass. The jaw crusher has a maximum feeding capacity of 800 mm and crushes the products, which first go to the washing screen. Here, the finest products are sent to the stock area with a screw washer, and the other products are sent to the cone crusher. The products coming out of the cone crusher are directed to the other screen and the vertical shaft impact crusher, allowing the desired products to be obtained from the final screen at high quality.

TBX-30 Vibrating Feeding Bunker CLK-110 Jaw Crusher TE-2060x3 2000x6000 3-Deck Vibrating Washing Screen HY-800 8000x8000 Screw Washer 20m3 Cone Crusher Feeding Bunker CC-300 Cone Crusher 20m3 Vertical Shaft Impact Crusher Feeding Bunker VSI-900 Vertical Shaft Impact Crusher TE-2060x4 2000x6000 4-Deck Vibrating Screen TE-2060x3 2000x6000 3-Deck Vibrating Screen Conveyor Belts, Control Cabin, Electrical Panel, and Automation System |

|

Voir tout

|

Bemærkninger |

|---|

|

Our stationary crushing and screening plant, with a capacity of 200-350 tons per hour, consists of a 30 m³ vibrating feeding bunker, mid-screen, CLK-110 jaw crusher, cone crusher, vertical shaft impact crusher, stock and return conveyors, control cabin, and automation system. Products transferred to the feeding bunker are separated from dirt and mud using the intermediate screen and are bypassed with a bypass conveyor. The material above the screen goes to the jaw crusher, while the products on the second level drop onto the jaw discharge conveyor, and the products on the lowest level are discarded as bypass. The jaw crusher has a maximum feeding capacity of 800 mm and crushes the products, which first go to the washing screen. Here, the finest products are sent to the stock area with a screw washer, and the other products are sent to the cone crusher. The products coming out of the cone crusher are directed to the other screen and the vertical shaft impact crusher, allowing the desired products to be obtained from the final screen at high quality.

TBX-30 Vibrating Feeding Bunker CLK-110 Jaw Crusher TE-2060x3 2000x6000 3-Deck Vibrating Washing Screen HY-800 8000x8000 Screw Washer 20m3 Cone Crusher Feeding Bunker CC-300 Cone Crusher 20m3 Vertical Shaft Impact Crusher Feeding Bunker VSI-900 Vertical Shaft Impact Crusher TE-2060x4 2000x6000 4-Deck Vibrating Screen TE-2060x3 2000x6000 3-Deck Vibrating Screen Conveyor Belts, Control Cabin, Electrical Panel, and Automation System |

Knuser Rubble Master RM90GO!

Knuser Sandvik QJ 341 +

Knuser Fabo ny INSTALLATION FIXE DE CONCASSAGE ET DE CRIBLAGE CAPACITE DE 150-250 TPH

Kæbeknuser McCloskey J45R

Siden 1 år på Via-Mobilis.dk

Siden 1 år på Via-Mobilis.dk